Protect your team, your site, and your reputation — with Cableaway’s Insulated Steel HASP with Hook. 6 x padlocks at one time, great for multiple trades working on the same equipment.

Designed for total electrical safety, this lockout device ensures that circuit breakers stay securely isolated during maintenance, preventing unexpected re-energisation that can cause serious injury or damage. Made from tough, reinforced nylon, it’s built to withstand demanding site conditions while ensuring your lockout tagout (LOTO) procedures remain fully compliant with Australian safety standards.

Quick and simple to install, with no tools required, this Insulated Steel HASP with Hook is ideal for electricians, contractors, and maintenance teams that prioritise workplace safety. Once fitted, it’s easy to lock off with a Cableaway safety padlock, giving you total peace of mind that circuits can’t be accidentally switched back on. Don’t take chances with live circuits — USE A CABLEAWAY LOCKOUT, EVERY TIME!

Secure Payments are easier than ever! Eway’s payment solutions

Delivery Option’s, you choose from our list of delivery partners

Manufactures warranty on all Cableaway sold products.

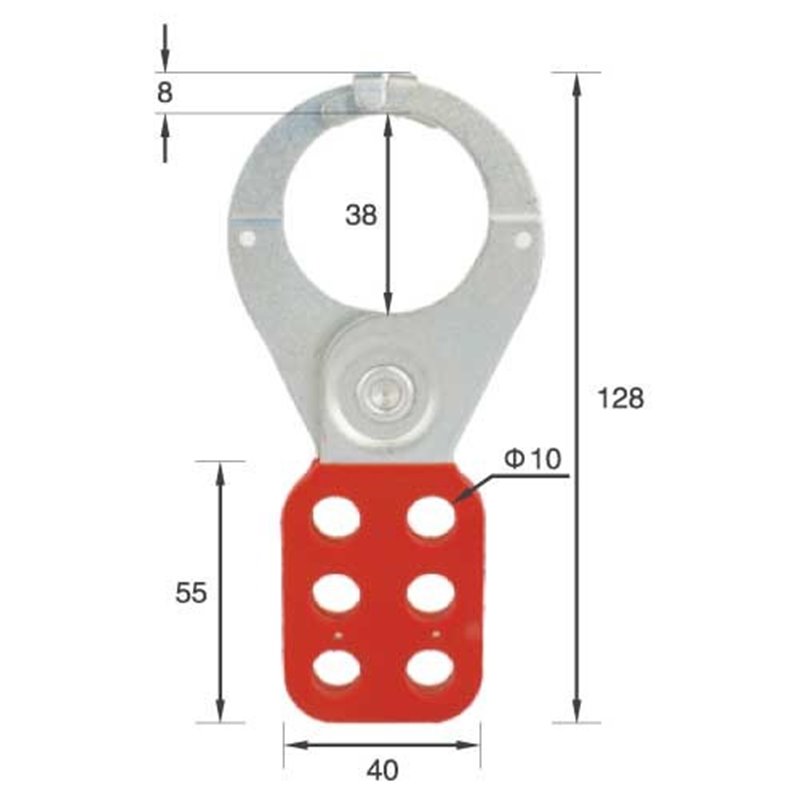

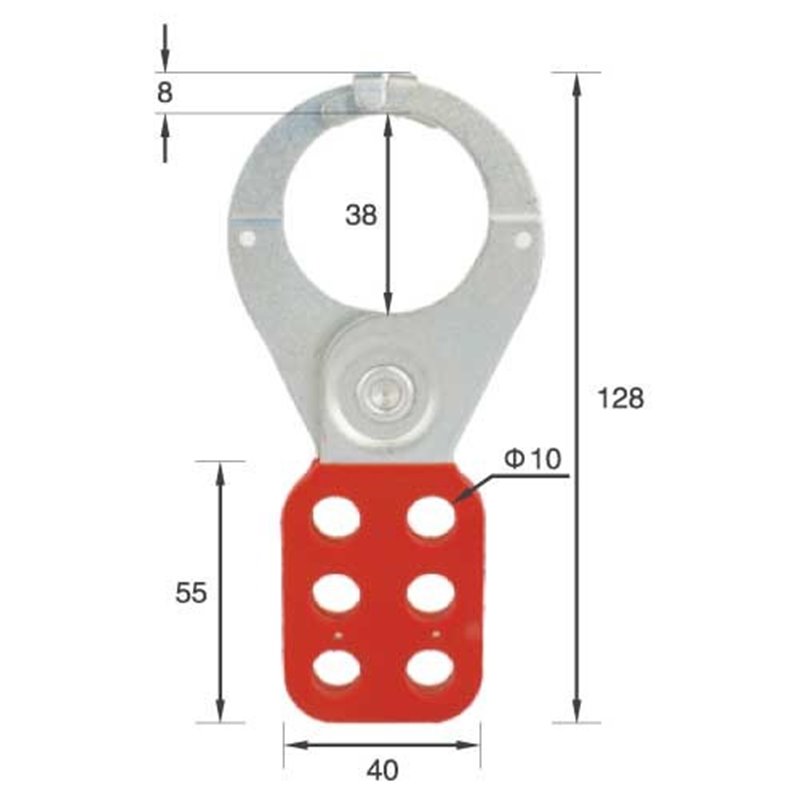

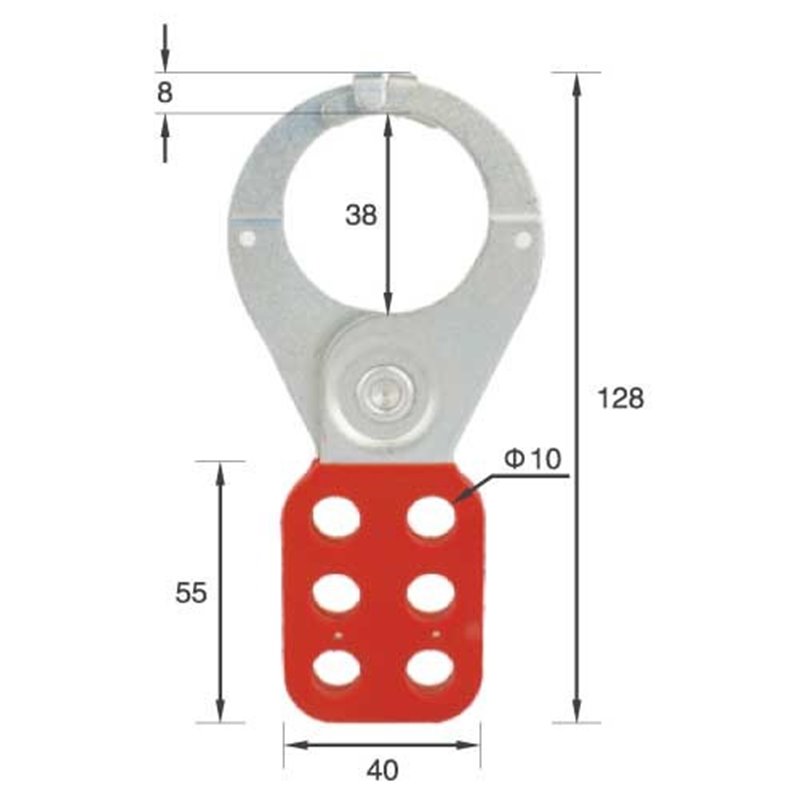

Steel Hasp with Hook

LOCKOUT SAFETY HASP 25mm ID (NYLON COATED) RED

Why Safety Padlocks and Hasps Are Essential

Safety padlocks and hasps are key components in any lockout tagout (LOTO) system, working alongside lockout devices to keep people safe and equipment securely isolated during maintenance or repairs.

While a lockout device physically blocks a switch, valve, or breaker from being turned back on, a safety padlock and hasp ensure that only authorised personnel can remove that block. This added layer of control prevents accidental or unauthorised re-energisation, which could cause severe injury or equipment damage.

Here’s what makes safety padlocks and hasps so important:

For complete electrical isolation, Cableaway Locks and HASPS: Never lock out without locking it down — every padlock and HASP is a small investment in a safer workplace.